Nanomanipulation and Tribology

From designing energy dissipation in single molecules up to unveiling the origins of static friction

Did you know that 23% of the world’s energy consumption comes from friction? And that it is impossible to predict the friction coefficient (µ) of a given contact a priori?

Although friction is nearly everywhere, we tend to notice it only when it is nearly absent, such as when we slip. Its ubiquitous presence across different length scales—from earthquakes and car engines to molecular machines—confers friction with immense practical importance. However, a lack of fundamental understanding of friction has hindered our predictive power.

Understanding and controlling friction is arguably one of mankind’s oldest quests. Although great scientists like Leonardo da Vinci provided the first scientific basis for friction five centuries ago, there remains no theoretical formulation of friction today. The inability to predict the friction coefficient for a given system and the challenge of reducing friction coefficients by even 1% attest to this. However, scientific progress occurs not out of necessity but because it is possible. In recent decades, new nanoscale experimental techniques have opened windows on frictional phenomena at the atomic and molecular levels.

In an effort to control friction at the atomic level and bridge different length scales, the fields of nanotribology and nanomanipulation have emerged. Over the years, our research group has made several high-impact contributions to this field, addressing key challenges such as:

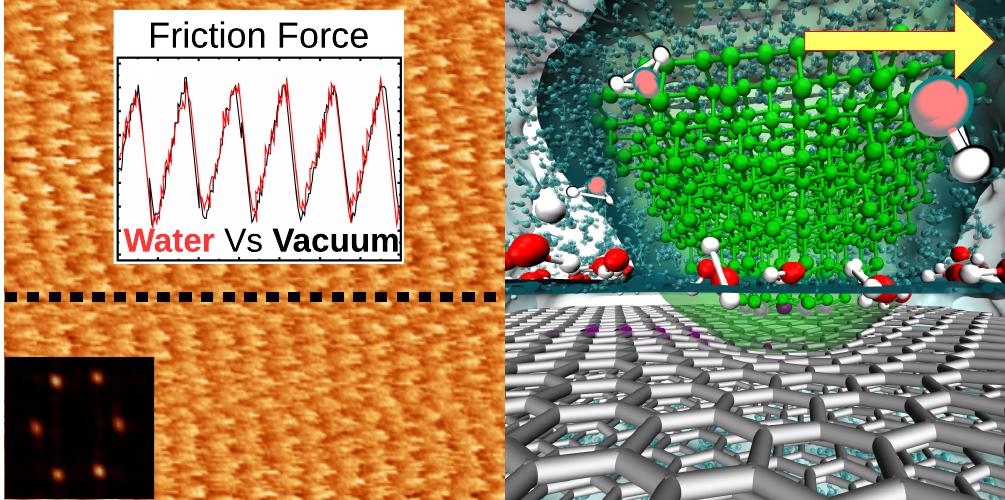

Any macroscopic surface exhibits a significant roughness thus leading to a certain number of true contact points at the interface. In this regard, atomic force microscopy (AFM), where a sharp tip is elastically driven on a solid substrate whilst measuring the associated friction, stands out as a tool of excellence in tribology. Despite its undisputed success, data interpretation in liquid and in ambient conditions is far from straightforward. In particular, it is unclear what is the role played by the solvent during sliding (e.g. if it is trapped under/around the tip), as well as other effects such as capillary condensation and presence of contaminants. We have shown that on a hydrophobic surface such as graphene, water molecules will mask these effects allowing us to recover the high resolution an ultra-low firction usually attained in much more elaborate Ultra-High-Vacuum (UHV) setups.

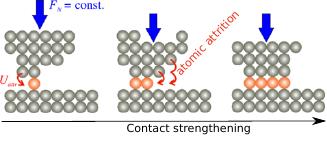

Around 350 A.D. the Greek philosopher Themistius reported that “One may more easily further the motion of a moving slider than to move a body at rest.” Despite the importance of this phenomena involved in a manifold of processes from earthquake dynamics down to microelectromechanics, our understanding of the atomistic origins governing it is rather limited. In this regard, some enlightenment is brought with the concept of contact aging, a process by which the strength between two adjacent materials (e.g. surface and slider) strengths with the hold time. Aging can be categorized into two different processes: quantitative and qualitative aging. The former, an established and widely accepted mechanism, describes the time-dependent increase of the real contact area due to plastic deformation and material creep. The latter, i.e. qualitative aging, is a process by which the strength per unit area changes with time as a result of interfacial chemistry (e.g. bond formation between the atoms of the surface and slider). In our group, we work in collaboration with several experimental groups to provide a live picture the dynamics of the atomic processes occurring at the interface. Recently, we have provided the first ever reported direct evidence linking contact aging to thermally activated bond formation (in a ultra-clean an controlled environment). This stepping stone, shed light on the distinction between contact “quantity” and “quality” thus paving new roads to a detailed understanding on the origins of the time dependence of static friction.

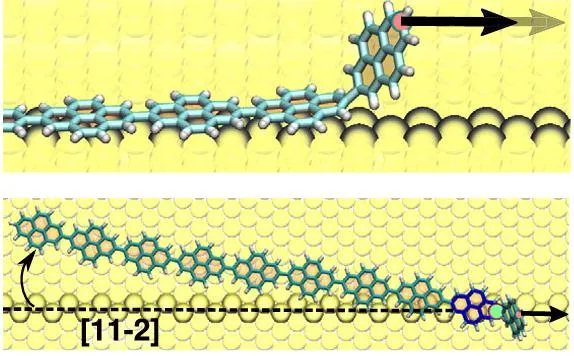

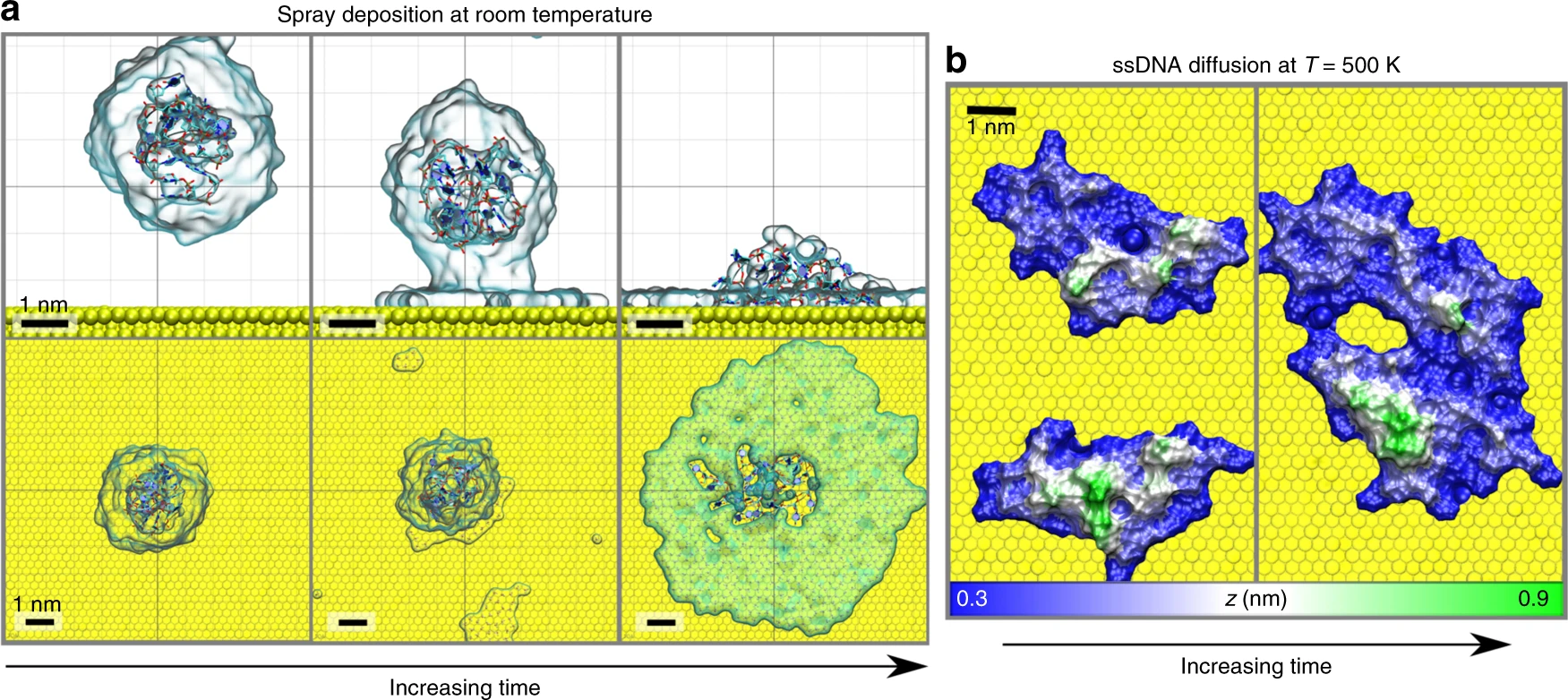

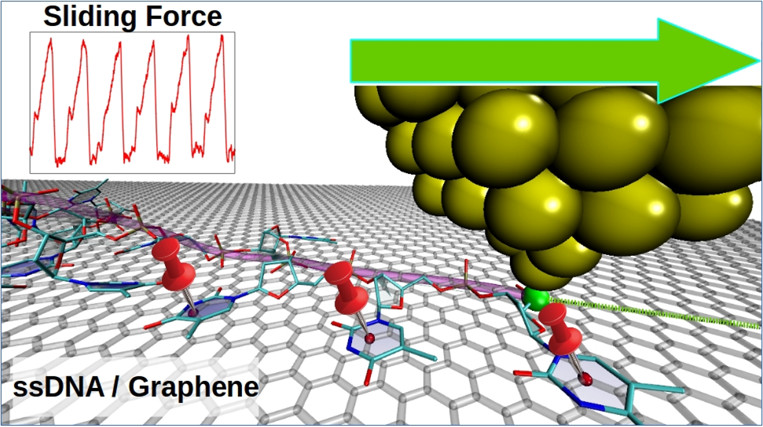

During the past decades we have witnessed a growing desire in miniaturization of devices down to the nanometer scale. Examples such as auto-assembling of molecular structures capable of meeting specific needs (e.g. synthetic photosynthesis, catalysis and molecular electronics) up to molecular-machines are promising avenues with a huge technological and economic interest in the decades to come. “Special problems occur when things get small […] and it might turn out to be advantages if we knew how to design for them”, said Feynman when discussing the prospects of building “infinitesimal machinery”. In particular, designing for more efficient molecular “machinery” as well as for better on-surface processes of molecular auto-organization requires a more detailed understanding of friction at a molecular level and more generally how energy is dissipated in such systems. Here we meet this challenge in a synergistic Theory-Experiment endeavour so pushing the limits of nanomanipulation. In particular, we provided the first measurement of the enthalpic stretching moduli of a single DNA nucleotide, real-time detection of single C-C bond rotation via external mechanical stimuli, and discovered a new form of near-frictionless sliding known as “flexible-superlubricity.”

Publications

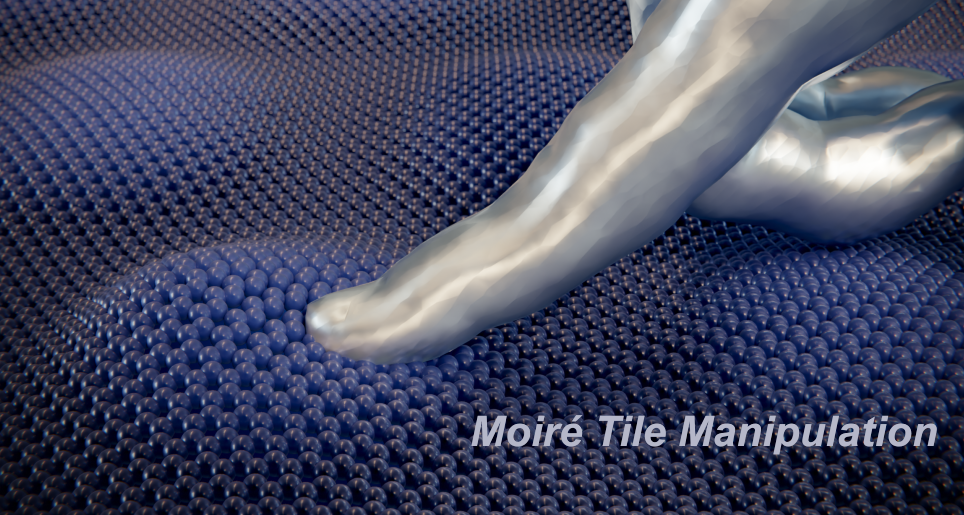

Z. Liu, J. G. Vilhena, A. Hinaut, S. Scherb, F. Luo, J. Zhang, T. Glatzel, E. Gnecco, and E. Meyer. “Moiré-Tile Manipulation-Induced Friction Switch of Graphene on a Platinum Surface“. Nano Letters 23 (10), 4693-4697 (2023).

J. G. Vilhena, R. Pawlak, P. D’Astolfo, X. Liu, E. Gnecco, M. Kisiel, T. Glatzel, R. Pérez, R. Häner, S. Decurtins, A. Baratoff, G. Prampolini, S. Liu and E. Meyer. “Flexible Superlubricity Unveiled in Sidewinding Motion of Individual Polymeric Chains“. Physical Review Letters 128 (21), 216102 (2022).

R. Pawlak, J. G. Vilhena, P. D’Astolfo, X. Liu, G. Prampolini, T. Meier, T. Glatzel, J. A. Lemkul, R. Häner, S. Decurtins, A. Baratoff, R. Pérez, S. Liu and E. Meyer. “Sequential Bending and Twisting around C–C Single Bonds by Mechanical Lifting of a Pre-Adsorbed Polymer“. Nano Letters 20, 652-657 (2020).

M. Vorholzer, J. G. Vilhena, R. Pérez, E. Gnecco, D. Dietzel and A. Schirmeisen. “Temperature Activates Contact Ageing in Silica Nanocontacts“. Physical Review X 9, 041045 (2019).

R. Pawlak, J. G. Vilhena, A. Hinaut, T. Meier, T. Glatzel, A. Baratoff, E. Gnecco, R. Pérez and E. Meyer. “Conformation And Mechanical Response of Spray Deposited Single Strand DNA on Gold“. Nature Communications 10 (1), 685 (2019) — featured in Nature Portfolio Chemistry.

J. G. Vilhena and R. Pérez. “Slippery in every direction“. Nature Materials 17, 852 (2018).

J. G. Vilhena, E. Gnecco, R. Pawlak, F. Moreno, E. Meyer and R. Pérez. “Stick-Slip motion of ssDNA over graphene“. Journal of Physical Chemistry B 122, 840 (2018).

J. J. Mazo, D. Dietzel, A. Schirmeisen, J. G. Vilhena and E. Gnecco. “Time strengthening of crystal nanocontacts”. Physical Review Letters 118 (24), 246101 (2017).

J. G. Vilhena, C. Pimentel, P. Pedraz, F. Luo, P. A. Serena, C. Pina, E. Gnecco and R Pérez. “Atomic-Scale Sliding Friction on Graphene in Water”. ACS Nano 10 (4), 4288 (2016).